Zinc Alloy Die Casting

Lefu la ho lahlela

Didiecasting ke eng?

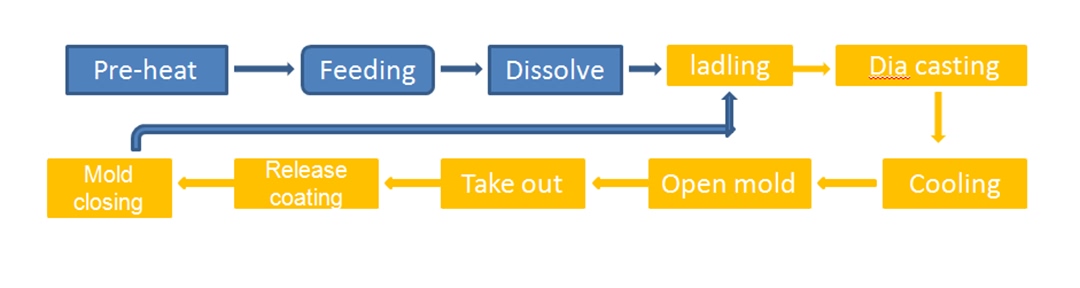

Khatello e bitsoa "die casting".

Mokhoa oa ho lahla moo mokelikeli o qhibilihisitsoeng oa alloy o tšeloang ka phaposing ea khatello,

sekoti sa hlobo ea tšepe se tlatsitsoe ka lebelo le phahameng, 'me mokelikeli oa alloy o tiisoa tlas'a khatello ea ho etsa casting.

Melemo le bobe ba ho lahla lefu:

Molemo: boleng bo botle bo phahameng ba tlhahiso e sebetsang hantle theko e ntle

Bothata: lisebelisoa tse lekantsoeng feela aluminium zinki magnesium lead tin ea koporo e ka sebelisoa ho lahla ho fihlela joale.

Thepa e turang, le lisebelisoa tsa theko e phahameng

Puisano e makatsang:

Phekolo ea likarolo tsa die casting holim'a metsi:

1.Ho penta

2. Ho roala ka phofo

3.Plating

4.Oxide anodizing

5.Ho pholisa, ho hlaba lehlabathe

6.Ho penta ka oli

7.Ho qhomisa lifaha

Phoso e kholo ea lefu la lefu

Ka hare: Stomata, lesoba le honyehang, lesoba la lehlabathe, le hlephileng

Bokaholimo: Crack, karohano e batang, mofuta o fosahetseng, billet e kholo, bubble, depositi ea khabone,

hlobo e khomarelang, moqomo, sag, trace, pockmark, scouring, crack, moropa o ka holimo, ho phunya

Die-casting ke e 'ngoe ea mekhoa e tsoetseng pele ea ho etsa tšepe.Ka ntlafatso e tsoelang pele ea theknoloji ea die-casting,

li-alloys tsa die-casting ha li sa lekanyetsoa ho litšepe tse se nang ferrous tse kang zinki, aluminium, magnesium le koporo.Boholo le boima ba 'mele -

likarolo tsa ho lahla li tla boela li eketsehe ha matla a mochine o bolaeang a ntse a eketseha, kahoo tebello ea ho lahleheloa ke lefu e pharaletseng haholo.

Die casting process e na le Bophahamo ba eona le eona e na le mefokolo ea eona.Boleng, boleng le theko ea lihlahisoa

e sebetswang ka dithulaganyo tse fapaneng di fapane.Mokhoa oa ho khetha ts'ebetso e nepahetseng ea sehlahisoa

ts'ebetso ts'ebetsong ea tlhahiso e hloka hore re ikhethele.

Lefu la ho lahlela

Didiecasting ke eng?

Khatello e bitsoa "die casting".

Mokhoa oa ho lahla moo mokelikeli o qhibilihisitsoeng oa alloy o tšeloang ka phaposing ea khatello,

sekoti sa hlobo ea tšepe se tlatsitsoe ka lebelo le phahameng, 'me mokelikeli oa alloy o tiisoa tlas'a khatello ea ho etsa casting.

Melemo le bobe ba ho lahla lefu:

Molemo: boleng bo botle bo phahameng ba tlhahiso e sebetsang hantle theko e ntle

Bothata: lisebelisoa tse lekantsoeng feela aluminium zinki magnesium lead tin ea koporo e ka sebelisoa ho lahla ho fihlela joale.

Thepa e turang, le lisebelisoa tsa theko e phahameng

Puisano e makatsang:

Phekolo ea likarolo tsa die casting holim'a metsi:

1.Ho penta

2. Ho roala ka phofo

3.Plating

4.Oxide anodizing

5.Ho pholisa, ho hlaba lehlabathe

6.Ho penta ka oli

7.Ho qhomisa lifaha

Phoso e kholo ea lefu la lefu

Ka hare: Stomata, lesoba le honyehang, lesoba la lehlabathe, le hlephileng

Bokaholimo: Crack, karohano e batang, mofuta o fosahetseng, billet e kholo, bubble, depositi ea khabone,

hlobo e khomarelang, moqomo, sag, trace, pockmark, scouring, crack, moropa o ka holimo, ho phunya

Die-casting ke e 'ngoe ea mekhoa e tsoetseng pele ea ho etsa tšepe.Ka ntlafatso e tsoelang pele ea theknoloji ea die-casting,

li-alloys tsa die-casting ha li sa lekanyetsoa ho litšepe tse se nang ferrous tse kang zinki, aluminium, magnesium le koporo.Boholo le boima ba 'mele -

likarolo tsa ho lahla li tla boela li eketsehe ha matla a mochine o bolaeang a ntse a eketseha, kahoo tebello ea ho lahleheloa ke lefu e pharaletseng haholo.

Die casting process e na le Bophahamo ba eona le eona e na le mefokolo ea eona.Boleng, boleng le theko ea lihlahisoa

e sebetswang ka dithulaganyo tse fapaneng di fapane.Mokhoa oa ho khetha ts'ebetso e nepahetseng ea sehlahisoa

ts'ebetso ts'ebetsong ea tlhahiso e hloka hore re ikhethele.