Ts'ebetsong ea machining, hangata ho kopana le hore tekanyo ea ho nepahala ha mochini ha e tšoauoa.Ka kakaretso, bareki ba tla hlalosa maemo a litšupiso ka mongolo o setšoantšong.Ehlile, naha ka 'ngoe le sebaka se na le maemo a sona, empa litekanyetso tse tloaelehileng ke tse latelang:

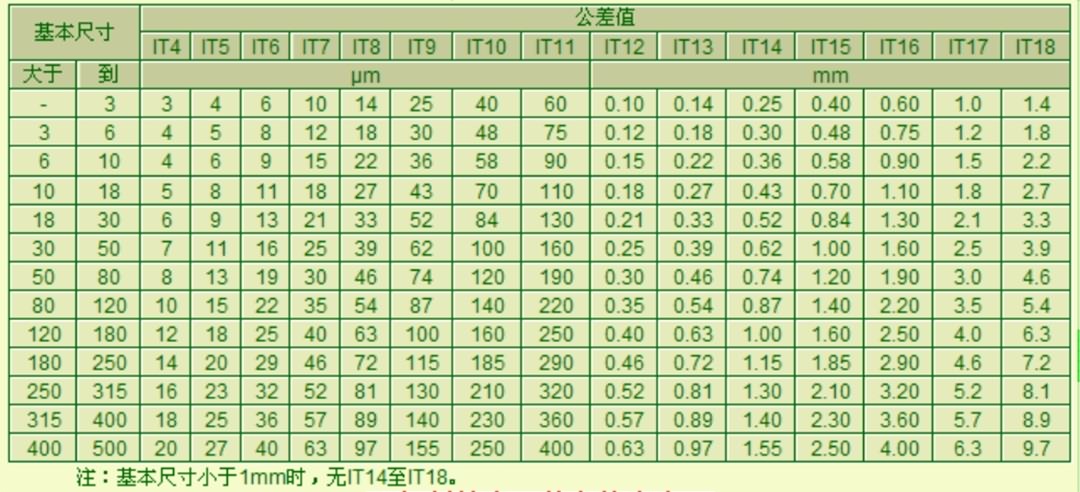

Ea pele ke ho latela maemo a machaba.E latelang ke tafole e tloaelehileng ea mamello ea boholo ba 0-500mm ka boemo bo nepahetseng ba 4 ho isa ho 18:

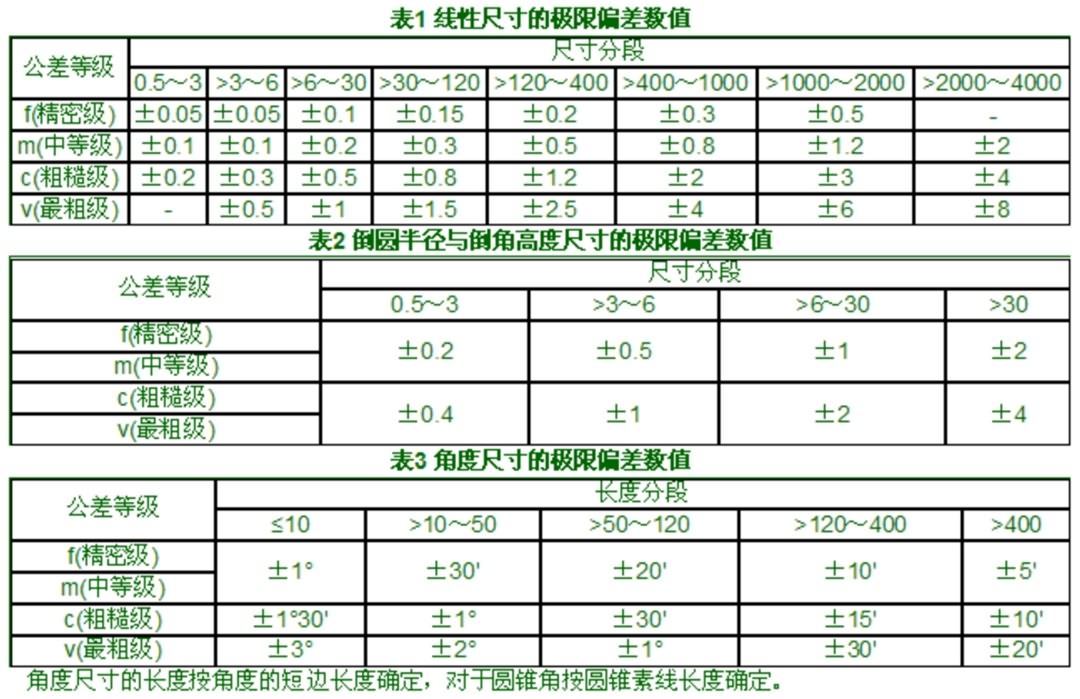

Ho ea ka maemo a machaba, ea bobeli e loketse ho itšeha ka tšepe le ho sebetsa ka kakaretso

Bophahamo ba Linear: boholo ba kantle, boholo bo ka hare, boholo ba mohato, bophara, radius, sebaka, joalo-joalo.

Angle dimension: boholo boo hangata bo sa bontsheng boleng ba angle, mohlala, angle e nepahetseng ea likhato tse 90.

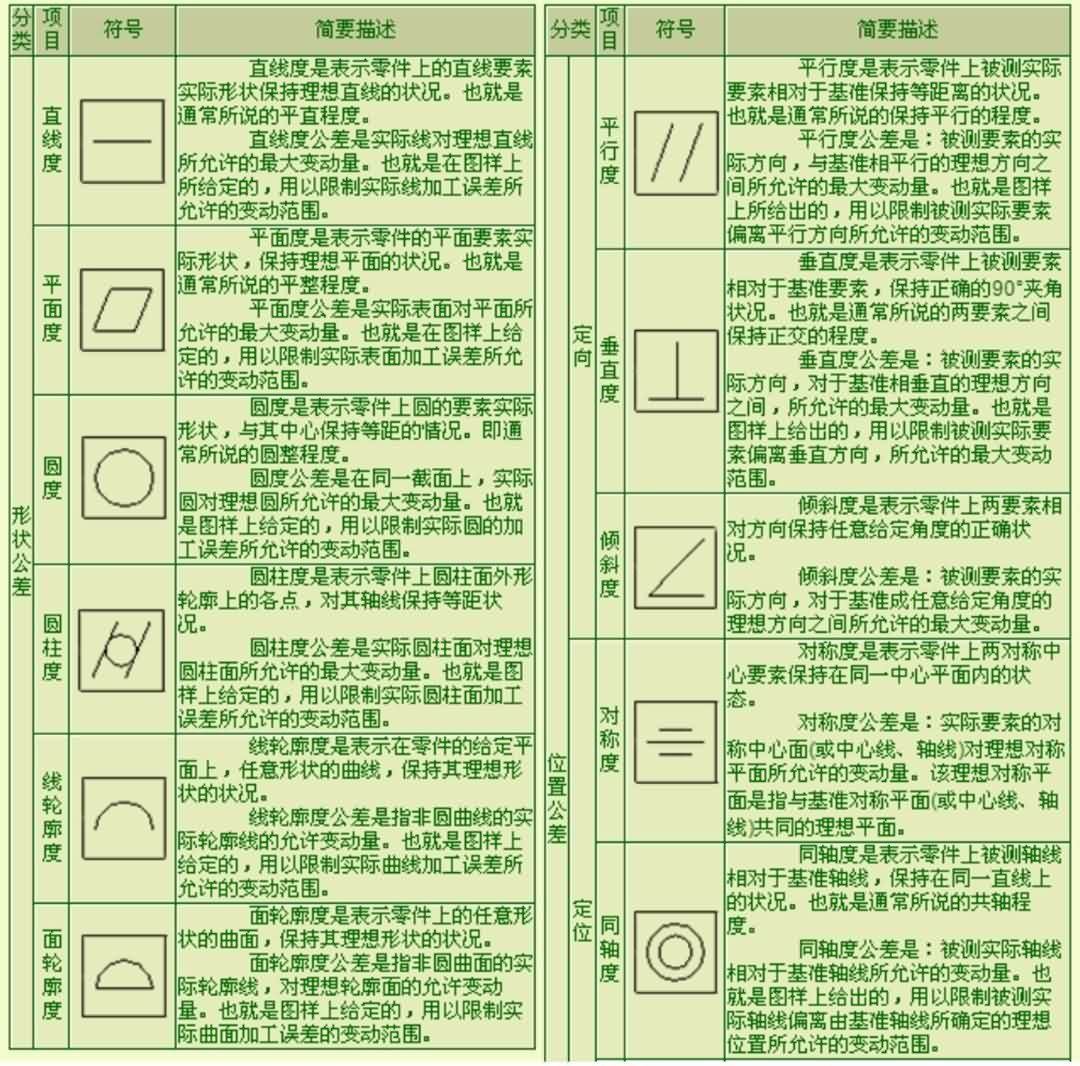

Mamello ea sebopeho e bolela phapang e felletseng e lumelletsoeng ke sebopeho sa sebopeho se le seng sa 'nete, se hlahisoang ke sebaka sa mamello ea sebopeho, se kenyelletsang lintlha tse' nè tsa sebopeho sa mamello, tataiso, boemo le boholo;Lintho tsa mamello ea sebopeho li kenyelletsa ho otloloha, ho bata, ho pota-pota, cylindricity, profil of line, profile ea flat wheel set, joalo-joalo.

Mamello ea boemo e kenyelletsa mamello ea lipallo, mamello ea maemo le mamello ea ho baleha.Sheba tafole e ka tlase bakeng sa lintlha:

Nako ea poso: Oct-12-2020